-

Anello di contatto rotatorio

-

Anello di contatto della capsula

-

Collettori ad anello del segnale

-

Giunto rotante a fibra ottica

-

Collettori ad anello ad alta frequenza

-

Attraverso l'anello di contatto del foro

-

Anello di contatto separato

-

Anello di contatto del pancake

-

Collettori ad anello a corrente forte

-

Slittamento Ring Components

-

Anello di contatto senza mercurio

-

Giunti rotanti idraulici pneumatici

-

Anello di contatto integrato

-

Slittamento Ring Solutions

-

WilliamL'aspetto dell'anello di contatto di JINPAT è buono, imballando con attenzione, entusiasmo di servizio, necessità di venire ancora

WilliamL'aspetto dell'anello di contatto di JINPAT è buono, imballando con attenzione, entusiasmo di servizio, necessità di venire ancora -

MartinConsegna, buona prestazione veloce e buona qualità, guardanti in avanti alla cooperazione seguente.

MartinConsegna, buona prestazione veloce e buona qualità, guardanti in avanti alla cooperazione seguente.

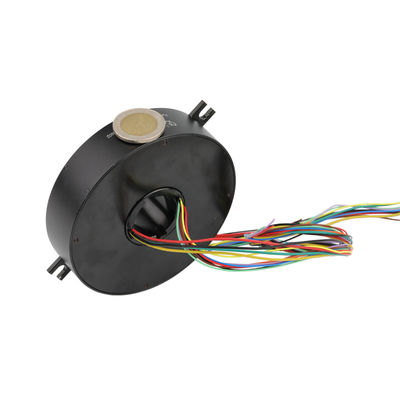

4/8 Circuiti Pancake Slip Ring con tensione nominale 220VDC/AC e corrente nominale 5A/2A

| Circuiti | 4/8 circuiti | Valutazione della tensione | 220 V CC/CA o superiore |

|---|---|---|---|

| Valutazione attuale | 5A/2A per circuito | Materiale di contatto | Metallo prezioso |

| Velocità di lavoro | 0 ~ 50rpm | Resistenza dielettrica | ≥1000V@50Hz(corrente) ≥500V@50Hz(segnale) |

| Resistenza all'isolamento | 500 MΩ a 500 V CC (corrente) 100 MΩ a 300 V CC (segnale) | Lunghezza del filo | Cavo statore: Cavo rotore da 300 mm: 300 mm |

| Temperatura operativa | -20 ° C ~+60 ° C. | Umidità | ≤60%RH |

| Valutazione IP | IP54 | Materiale abitativo | Nero di ossidazione della lega di alluminio |

| Spessore | 6 mm | Tipo di contatto | Metallo Nobel |

| Metodo di installazione | Lo statore è fissato sul mandrino fornito dal cliente | ||

| Evidenziare | 4/8 Circuiti Pancake Slip Ring,220VDC/AC Anello di scivolo di tensione nominale,5A/2A corrente nominale Pancake Slip Ring |

||

La serie LPK è un gruppo di anelli collettori a disco prodotti da JINPAT con uno spessore minimo di 6 mm. Progettati esclusivamente per sistemi rotanti con spazio di installazione verticale limitato, questi anelli collettori sono dotati di anelli in rame e contatti a spazzola che circondano un foro centrale per la massima efficienza dello spazio.

- Capacità di alta velocità di rotazione

- Contatto affidabile con design leggero

- Funzionamento con rumore fisico estremamente basso

- Rotazione continua a 360° per la trasmissione di potenza e segnali

- Nessuna interferenza o interruzione della connessione durante il funzionamento

- Opzione encoder fotoelettrico pronto all'uso

- Scelta di alberi pieni o cavi

- Consegna rapida disponibile

- Soluzioni personalizzate su misura per le tue esigenze

| Elettronico ed elettrico | Meccanico | ||

|---|---|---|---|

| Circuiti | 4 circuiti × 5A / 8 circuiti × 2A | Velocità di lavoro | 0-50 giri/min |

| Tensione di lavoro | 220VDC/AC | Contatto | Metallo nobile |

| Rigidità dielettrica | ≥1000V@50Hz (Corrente) ≥500V@50Hz (Segnale) | Alloggiamento | Ossidazione nera in lega di alluminio |

| Isolamento | 500MΩ@500VDC (Corrente) 100MΩ@300VDC (Segnale) | Lunghezza del filo | Filo statore: 300 mm / Filo rotore: 300 mm |

| Ambiente | Osservazioni | ||

| Temperatura | -20°C a +60°C | Metodo di installazione | Statore fissato sul mandrino fornito dal cliente |

| Umidità | ≤60%UR | ||

| Grado IP | IP54 | ||

- Macchinari per l'imballaggio e l'avvolgimento

- Sistemi di movimentazione dei semiconduttori

- Macchinari industriali

- Macchinari per l'esposizione di mostre

- Apparecchiature mediche

- Tavole rotanti indicizzatrici

- Apparecchiature di controllo del processo

- Struttura di oltre 12.000 metri quadrati con oltre 500 dipendenti

- Destinatario del premio National High and New Technology con 69 brevetti

- Collaborazioni globali con aziende rinomate

- Oltre 10.000 progetti di successo in applicazioni civili, militari, commerciali e industriali

- Fondata nel 1996 con oltre 20 anni di esperienza nella produzione e nella ricerca e sviluppo

- Soluzioni personalizzate gratuite per anelli collettori per diverse esigenze di apparecchiature

- Servizio di consegna rapida

Siamo specializzati nello sviluppo, progettazione e produzione di anelli collettori di alta qualità, offrendo soluzioni complete per sistemi rotanti.

Un anello collettore è un dispositivo elettromeccanico che consente la trasmissione di potenza e segnali elettrici tra strutture fisse e rotanti. Migliora le prestazioni meccaniche, semplifica il funzionamento del sistema ed elimina i cavi pendenti soggetti a danni nei giunti mobili.

- Anelli collettori elettrici (a capsula, a foro passante, in miniatura)

- Anelli collettori di segnale (USB 2.0/3.0, giunti rotanti in fibra ottica, alta frequenza)

- Unioni rotanti pneumatiche/idrauliche

- Anelli collettori personalizzati

- Serie di grandi volumi

La selezione richiede dettagli sui parametri operativi della tua applicazione, tra cui il numero totale di circuiti, la tensione e la corrente per circuito, la velocità di funzionamento e il tipo di montaggio. Per soluzioni personalizzate o assistenza nella selezione, contatta il nostro team di ingegneri.

Sì, i nostri ingegneri sviluppano soluzioni personalizzate perfette su misura per le tue esigenze specifiche. Contattaci per discutere le esigenze della tua applicazione.

Valutazione complessiva

Rappresentazione del rating

Di seguito è riportata la distribuzione di tutte le valutazioniTutte le recensioni